The phenomenon that utilizes high-energy particles to bombard the surface of the solid target and thus atoms platter from the surface of the solid target after exchanged kinetic energy with high-energy particles is called sputtering. The sputtered atoms have a certain momentum and hence can form sputtering film after re-deposit and condensate on the surface of the solid substrate. Sputtering coating can be divided into diode sputtering, triode sputtering and magnetron sputtering according to the electrode structure.

Some Introduction of Magnetron Sputtering

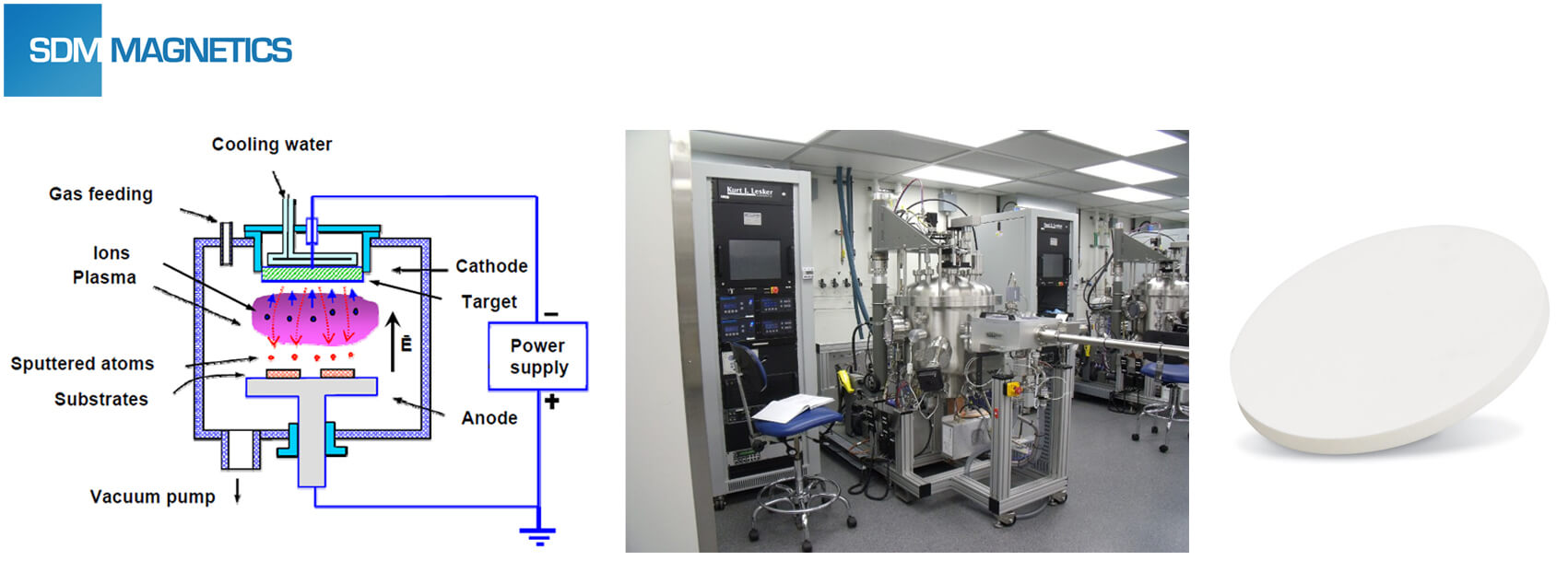

Normal DC diode sputtering apply negative potential to the sputtering target (cathode target) and anode will place the substrate holder. Introduce sputtering gas (argon gas) to chamber, then apply a strong current between cathode and anode when pressure risen to 1 ~ 10Pa, hence produced glow discharge and formed plasma. Positive ions Ar+ will rapidly fly to cathode under the action of electric field, thus bombard the cathode target and generated sputtered atoms. On the other hand, ionization collision will be ongoing between electrons and argon atoms, then generate new positive ions, secondary electrons and sustain discharge. Finally, target atoms fly and deposited to substrate and formed the thin film.

In order to enhance the deposition rate of diode sputtering and weaken the thermal effect on the film quality which caused by impact between secondary electrons and substrate, magnetron sputtering were conceived and soon became one of mainstream sputtering technology. Magnetron sputtering equipment introduced magnetic field to DC sputtering cathode target and utilize Lorenz power of the magnetic field to bind and extend the trajectory of electron motion in the electric field, then improve collision probability between electrons and gas atoms, thus enhance ionization rate of gas atoms. In this case, energetic ions for target bombardment are increasing and high-energy electrons which bombarded substrate are decreasing.

Magnetron sputtering build a circular and closed magnetic field on the cathode target surface of diode sputtering. Magnetic field is generated by the magnet array in the target body and has transverse magnetic field component which parallel to the target surface. Transverse magnetic field will constitute an orthogonal electromagnetic field with the electric field which perpendicular to the target surface, and form an electron trap which parallel to the target surface to bind secondary electrons.

Electrons e will be accelerated under the action of electric field E and collide with argon atoms during flying to the substrate. Ar+ and electron will be ionized out when the electron has enough energy and electron fly to substrate and Ar+ rapidly flies to cathode under electric field E, then bombard the target surface and generated sputtered particles. The neutral target atoms deposit on the substrate and forms the thin film. The sputtered secondary electrons will be accelerated in the cathode dark area and thereby fall into electron trap during fly to substrate, thus exhibit cyclotron motion near the target surface due to the action of the Lorenz force. The motion of electron e1 is bound to the plasma zone near the target surface by electromagnetic field and it significantly increases the probability of impact ionization, then enhances ionization rate of the gas atom and Ar+ ion in this area. Therefore, high-rate deposition of magnetron sputtering can be achieved.

The Role of Magnetic Field in Magnetron Sputtering

Magnetron sputtering mainly included the process of discharge plasma transportation, target etching and thin film deposition. Actually, magnetic field has certain influence on each process. When apply orthogonal magnetic field to magnetron sputtering system, electrons exhibit helical motion due to the action of the Lorenz force and move to anode gradually along with continuous collision. These electrons have relatively low energy when arrived anode and generate low bombardment heating on the substrate. Magnetic action area near the target surface has relatively higher electron concentration because of the binding effect of target magnetic field. Thus concentration near the substrate is significantly lower and has uniform distribution. The electron density for target sputtering is low and therefore causes very low bombardment heating.

Introduction of magnetic field will bind and extend the trajectory of electron motion and greatly enhance the collision probability between electron and gas, then promote the occurrence of ionization. That is why magnetron sputtering has excellent deposition rate. Besides, the presence of magnetic field will enable magnetron sputtering system operates under the relatively low pressure which helps ions to reduce collision in sheath area and bombard target with higher kinetic energy. In the meanwhile, reduce collision between sputtered target atoms and neutral gas, thus avoid scattering of target atoms, and finally improve deposition rate and quality.

Target magnetic field can effectively bind the trajectory of electron motion, hence affect plasma characteristics and etching path. In fact, etching uniformity can be enhanced by improving uniformity of target magnetic field and further raise utilization of target. The reasonable magnetic field distribution can also enable ameliorate stability during the sputtering process. Arguably, strength and distribution of the magnetic field are extremely important to the magnetron sputtering.